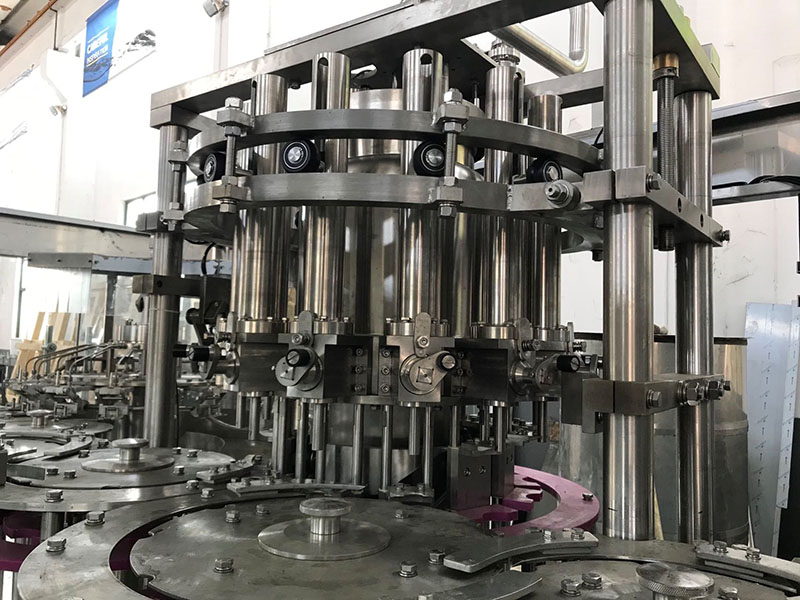

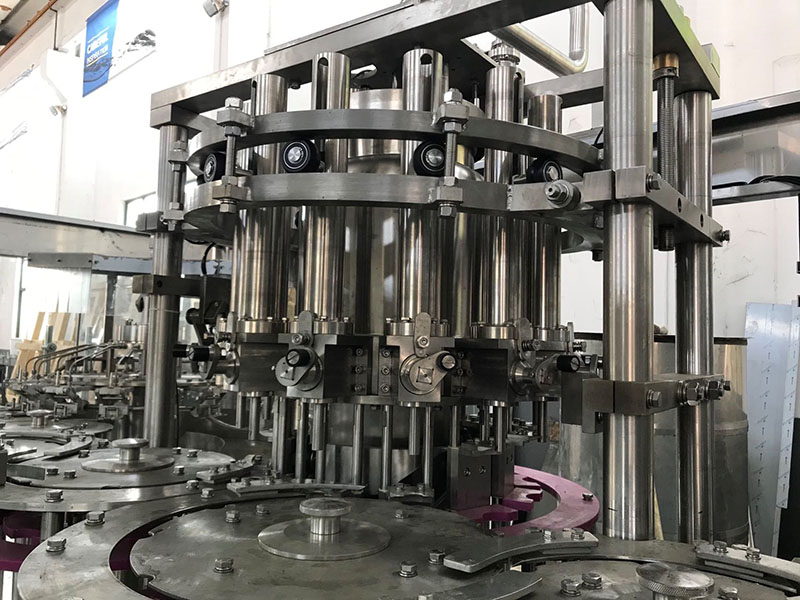

The bottle is filled with a positioning bottle hanging device, which runs smoothly and reliably. The bottle mouth passes through the travel guide rail of the plunger filling valve on the hanging plate, and then the valve opening mechanism opens under the action of the cylinder to inject certain material Pulp (non-contact filling). When the filling valve set liquid level is reached, the closing valve mechanism is closed, and then the bottle is exported from the primary particle filling through the transition steel dial wheel and transmitted to the next process-secondary slurry filling.

The bottle is filled with a positioning bottle hanging device, which runs smoothly and reliably. The bottle mouth passes through the travel guide rail of the plunger filling valve on the hanging plate, and then the valve opening mechanism opens under the action of the cylinder to inject certain material Pulp (non-contact filling). When the filling valve set liquid level is reached, the closing valve mechanism is closed, and then the bottle is exported from the primary particle filling through the transition steel dial wheel and transmitted to the next process-secondary slurry filling. The bottle is filled with a positioning bottle hanging device, which runs smoothly and reliably. The bottle mouth is operated through the travel guide rail of the plunger filling valve on the hanging plate, and then the valve opening mechanism is opened under the action of the cylinder to inject some material thick slurry (non-contact filling). When the filling valve closing mechanism is closed at the stroke set level, then the bottle is exported from the secondary slurry filling through the transition steel dial wheel and transmitted to the next process of capping

The bottle is filled with a positioning bottle hanging device, which runs smoothly and reliably. The bottle mouth is operated through the travel guide rail of the plunger filling valve on the hanging plate, and then the valve opening mechanism is opened under the action of the cylinder to inject some material thick slurry (non-contact filling). When the filling valve closing mechanism is closed at the stroke set level, then the bottle is exported from the secondary slurry filling through the transition steel dial wheel and transmitted to the next process of capping After filling, the bottle enters the Capping machine through the transmission star wheel. The stop knife on the Capping machine gets stuck in the bottleneck area and works with the bottle guard plate to keep the bottle upright and prevent rotation. The Capping head rotates and rotates under the main shaft of the Capping machine, to grasp the Cap, Put Cap, Capping and Cap off under the action of the cam, to complete the whole Cap sealing process. The Capping head adopts a magnetic and constant torque device. When the spin Cap is removed through the split Cap plate, the top Cap covers the Cap and rights it to ensure that the Cap is positioned correctly in the spin Cap mold and ensure the quality of the Capping. When the cap is completed, the cap head overcomes the magnetic skid and will not damage the cap, and the cap rod lifts the cap out of the cap mold. The cap plate transmits power through the pin wheel and the cap head to ensure that its movement is synchronized with the cap machine. The cap enters the cap plate through the Cap channel, and then the cap wheel transfers the cap to the cap head separately at the station.The Cap is transported to the Cap Arranging device through the Cap Loader. After the Cap enters the Cap device through the back Cap recovery device with the opening of the upward position. When the lid is opened down, the Cap will enter the back Cap tube through the back Cap recovery device and return to the Cap Arranging device, thus ensuring that the lid from the Cap Arranging device emerges. A photoelectric detection switch is provided in the Cap channel between the Cap Arranging Device and the Cap disinfection machine and the Cap disinfection and the main Machine, which controls the start and stop of the Cap device through the accumulation of the lid on the Cap channel.

After filling, the bottle enters the Capping machine through the transmission star wheel. The stop knife on the Capping machine gets stuck in the bottleneck area and works with the bottle guard plate to keep the bottle upright and prevent rotation. The Capping head rotates and rotates under the main shaft of the Capping machine, to grasp the Cap, Put Cap, Capping and Cap off under the action of the cam, to complete the whole Cap sealing process. The Capping head adopts a magnetic and constant torque device. When the spin Cap is removed through the split Cap plate, the top Cap covers the Cap and rights it to ensure that the Cap is positioned correctly in the spin Cap mold and ensure the quality of the Capping. When the cap is completed, the cap head overcomes the magnetic skid and will not damage the cap, and the cap rod lifts the cap out of the cap mold. The cap plate transmits power through the pin wheel and the cap head to ensure that its movement is synchronized with the cap machine. The cap enters the cap plate through the Cap channel, and then the cap wheel transfers the cap to the cap head separately at the station.The Cap is transported to the Cap Arranging device through the Cap Loader. After the Cap enters the Cap device through the back Cap recovery device with the opening of the upward position. When the lid is opened down, the Cap will enter the back Cap tube through the back Cap recovery device and return to the Cap Arranging device, thus ensuring that the lid from the Cap Arranging device emerges. A photoelectric detection switch is provided in the Cap channel between the Cap Arranging Device and the Cap disinfection machine and the Cap disinfection and the main Machine, which controls the start and stop of the Cap device through the accumulation of the lid on the Cap channel.| model | RXGGF16-16-16-5 |

| The number of stations | Washing Head 16 Pulp filling Head 16 Juice filling Head 16 Capping Head 5 |

| production capacity | 5500 bottles / hour (300ml / bottle, bottle mouth: 28) |

| bleed pressure | 0.7MPa |

| gas consumption | 1m3/min |

| Bottle water pressure | 0.2-0.25MPa |

| Water consumption of the bottle | 2.2 Tons / h |

| Power of main motor | 3KW |

| The power of the machine | 7.5KW |

| external dimensions | 5080×2450×2700 |

| The weight of the machine | 6000kg |