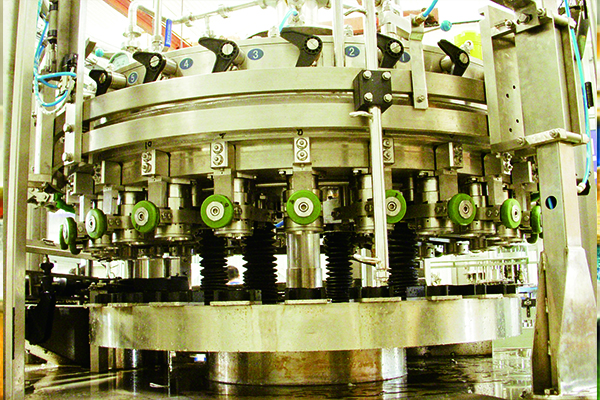

● This machine works harmoniously with chain plate conveyor belt; ● This machine integrated 2 functions: 1. filling the empty cans, 3. sealing the cans. ● High precision beer filling nozzle , ensure high filling precision & filling smoothly & steadily ● Isobaric Pressure filling nozzles which ensure minimal loss of CO2 from the drink ● All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean ● CIP ( clean in place) sideway pipeline in-build, can connect with CIP station or Tap water to clean ● Ingenious lid loading device to make sure no can, no lid loading, no sealing; ● Energy saving model, one motor can process all actions; ● Full sealing effect make sure to be suitable for liquid packing can; ● The machine suitable for all kinds of cans with same diameter, height can be adjusted easily; ● Twice sealing tech to make well sealing effect, no leakage;

● This machine works harmoniously with chain plate conveyor belt; ● This machine integrated 2 functions: 1. filling the empty cans, 3. sealing the cans. ● High precision beer filling nozzle , ensure high filling precision & filling smoothly & steadily ● Isobaric Pressure filling nozzles which ensure minimal loss of CO2 from the drink ● All 304 stainless steel contact parts & liquid tank, fine polish, easy to clean ● CIP ( clean in place) sideway pipeline in-build, can connect with CIP station or Tap water to clean ● Ingenious lid loading device to make sure no can, no lid loading, no sealing; ● Energy saving model, one motor can process all actions; ● Full sealing effect make sure to be suitable for liquid packing can; ● The machine suitable for all kinds of cans with same diameter, height can be adjusted easily; ● Twice sealing tech to make well sealing effect, no leakage;

★ When accident system automatic stop & alarm ★ Emergency switch when accident ★ PLC control full-automatic working, inverter in-build, speed adjustable ★ Touch-screen Control Panel, easy operate

★ When accident system automatic stop & alarm ★ Emergency switch when accident ★ PLC control full-automatic working, inverter in-build, speed adjustable ★ Touch-screen Control Panel, easy operate | Model | GF12-2 | GF18-4 | GF24-6 | GF32-8 |

| Capacity | 1500-2000cans/hour | 2000-3500CPH | 4000-6000CPH | 8000-10000CPH |

| Can Volume | 200-550ml | |||

| Can diameater | 50-70mm | |||

| Bottle high | 120-170mm | |||

| Machine power | 1.5KW | 2.2KW | 3.7KW | 5.5KW |

| Machine size | 175x120x195CM | 305x175x220CM | 340X195X220CM | 350x235x225CM |